Call us today Tel: 001 -

RSSUS Services Inc.

Part of Risk Security Services US Inc

RSS in Partnership with Seward Safety

Seaward Safety keeping you compliant

Aviation Vertical Escape Chutes

The RSS DM-

The DM-

For severe weather environments the system can be fitted with electrical heat tracing to ensure availability on demand even in the harshest of conditions.

1.0 DESCRIPTION OF SYSTEM

The system is comprised the following main components:

Qty 1 x Chute container with lower trap door, hinged lid and hydraulic dampened arms. The chute container depth (excluding the lid) can vary dependent upon the length of chute required to be packed inside, however the standard dimensions are:

890mm x 890mm x 1219mmH (35’’ x 35’’ x 48’’H). Height can vary dependent on control tower chute height.

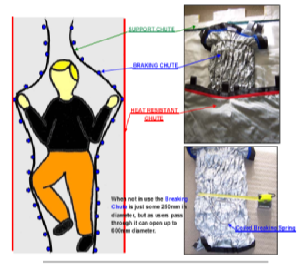

Three Layered Vertical Escape Chute designed to support a dead weight of 2 tonnes. Heat resistant to 600o C, melting point 800o C. The chute length varies dependent upon the height of the control tower above the deck exit location. Note: 1 meter air gap is required at the bottom for evacuees to exit

2.0 Chute Container

The system is comprised a deck mounted chute container into which the chute, is packed. The container is fabricated from powder coated mild steel.

The main chute container is painted red with the lower trap door safety yellow and red chevrons and the words ‘Escape Chute’. In all cases an epoxy three coat preparation and painting system is provided with supporting fabrication and painting certificates, metal mill test reports, welding certs, UV and UT reports provided. All paint applications are suitable for offshore marine environments.

The deck mountable chute container requires a cut out of approx. 900m x 900m (35.4” X 35.4”) or fits into a deck mounted support frame (supplied as an option by RSS and has a hydraulically dampened lid and lower trap door. The lid assembly is safety yellow and decaled with red chevrons and the wording ‘Escape Chute’. A serial number identification plate is provided and lists the system serial/model number with the date of manufacturer and RSS emergency contact telephone numbers.

3.0 Vertical Three Layer Chute

Layered Vertical Escape Chute designed to support a dead weight of 2 tones and heat resistant to 650 degrees with a melting point of 800 degrees. The Chute length varies dependent on operating height; however in all cases a one meter air gap is required at deck level for evacuees to exit the chute.

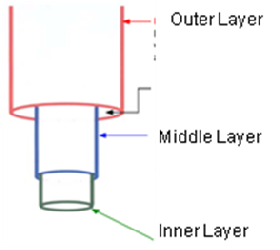

Layer 1

The outer ‘Flame-

There is a space between the outer and middle layer designed to reduce the radiated heat transferred to the middle & inner chute layers.

Layer 2

The middle ‘Braking’ layer, this is fitted with a series of stainless steel coiled springs sewn into the material. These springs have a small diameter designed arrest descent as the individual descends. Descent speed through the chute is adjusted by the individual extending or withdrawing arms & legs.

The evacuee only needs to apply pressure on the chute's interior wall with legs and arms, the more pressure, the more you slow down, less pressure and you will speed up.

In all cases descent speed is controlled and safe.

Layer 3:

The Inner Layer -

4.0 Material Specification

INNER CHUTE LAYER:

MATERIAL : Polyester

WARP : Polyester

Breaking Tenacity : 185.2 Tensile Strength (Kgf) (C.R.E. Grab Method)

Breaking Tenacity : 82.7 Tearing Strength (Kgf) (C.R.W. Tongue Method)

Flame Resistant : None

Decomposing Temperature : 260 Degrees "C"

WEFT : Polyester

Breaking Tenacity : 184.9 Tensile Strength (Kgf) (C.R.E. Grab Method)

Breaking Tenacity : 80.4 Tearing Strength (Kgf) (C.R.W. Tongue Method)

Flame Resistant : None

Decomposing Temperature : 260 Degrees "C“

MIDDLE CHUTE LAYER:

MATERIAL : Nylon 1901

WARP : Nylon 1901

Breaking Tenacity : 52.0 Tensile Strength (Kgf) (C.R.E. Grab Method)

Breaking Tenacity : 3.0 Tearing Strength (Kgf) (C.R.W. Tongue Method)

Flame Resistant : None

Decomposing Temperature : 215 Degrees "C"

WEFT : Nylon 1901

Breaking Tenacity : 51.9 Tensile Strength (Kgf) (C.R.E. Grab Method)

Breaking Tenacity : 2.8 Tearing Strength (Kgf) (C.R.W. Tongue Method)

Flame Resistant : None

Decomposing Temperature : 215 Degrees "C"

MATERIAL : Stainless Steel Springs AIS 1304

Breaking Tenacity : 150 Kgf/mm2 (1471N/mm2)

OUTER CHUTE LAYER:

MATERIAL : Electro Glass, Fiber Glass (Gray / Silver)

Weight : 440g/m2

Softening Point : 800 Degrees "C"

Temperature Limit for Continuous use : 550 to 600 Degrees "C"

Tensile Strength -

Tensile Strength -

Download Basis of Design PDF

For more information, please call and one of our representatives, we will be happy to answer any questions you may have.

Tel: 281 676 8008 Fax: 281 676 8033

Email: sales@rssusservices.com

Powered by Serif WebPlus